How to Water a Forklift Battery

What Are The Best Practices, Mistakes to Avoid For Your Forklift Battery?

Let’s face it forklift batteries aren’t cheap. And neither is downtime.

Yet one of the simplest ways to extend a battery’s life and avoid unexpected breakdowns is often overlooked: watering

It might not sound like much, but neglecting this step can lead to reduced battery performance, shorter lifespan, and more costly repairs than you’d like to admit. Whether you manage a single truck or a fleet across the West Midlands, knowing when and how to water a forklift battery is essential to keeping your operation running smoothly.

Free Site Survey

Rapid Breakdown Callout

Free Fleet Assesment

Toyota Class Service at Low Cost

Contents:

Because at Easy Truck, we’re more than just forklift suppliers, we’re invested in your uptime. That means helping you keep your battery-powered forklifts running efficiently, day after day. Whether it’s through expert maintenance advice, practical battery care training, or on-site support for your fleet, we go beyond simply delivering equipment. We deliver the knowledge and backup that keeps your business moving.

Battery Basics: Why Watering Matters

Most forklifts run on lead-acid batteries. Inside those batteries is a chemical solution a mix of sulphuric acid and water that powers your truck. Over time, and especially during charging, the water in that mix evaporates. When the electrolyte level drops too low, it exposes the battery plates to air. That’s when problems start.

Not only can this shorten the battery’s life, but it can also lead to reduced lifting power, sluggish acceleration, and even total failure. On the other hand, overfilling the battery can cause electrolyte to overflow during charging, damaging cables and causing corrosion.

So what’s the goal? Keep the electrolyte level just right not too low, not too high.

Here’s why it matters:

- Protects your investment – Batteries are expensive. Watering them properly keeps them working for years longer.

- Improves safety – Low electrolyte levels can lead to overheating and dangerous acid spills.

- Boosts performance – A properly watered battery delivers steady, reliable power throughout the shift.

- Reduces running costs – More uptime. Less need for emergency replacements.

- Supports sustainability – Well-maintained batteries are more energy efficient and reduce waste.

At Easy Truck, we help businesses across the West Midlands keep their batteries in top condition. We understand that battery health directly affects performance, safety, and operational costs. That’s why our support doesn’t end at delivery, it includes hands-on maintenance guidance, scheduled service visits, and proactive advice tailored to your fleet. Because a neglected battery doesn’t just drain power, it drains profits, schedules, and trust with your own customers.

When & How Often to Water a Forklift Battery

The golden rule? Only water a forklift battery after it’s been fully charged and cooled down.

Charging causes the electrolyte to expand. If you top up the battery before charging, you risk overflow and acid spillag, which ise not ideal in a busy warehouse.

How often should you water a battery? That depends:

- Light use (1 shift/day): Check weekly

- Heavy use (multiple shifts): Check every 5–10 charge cycles

- Older or reconditioned batteries: May need more frequent attention

- High-temp environments: Water evaporates faster, so increase inspections

Don’t rely on guesswork; visual checks, float indicators, and manufacturer guidelines are key. A small change in routine can make a big difference in lifespan.

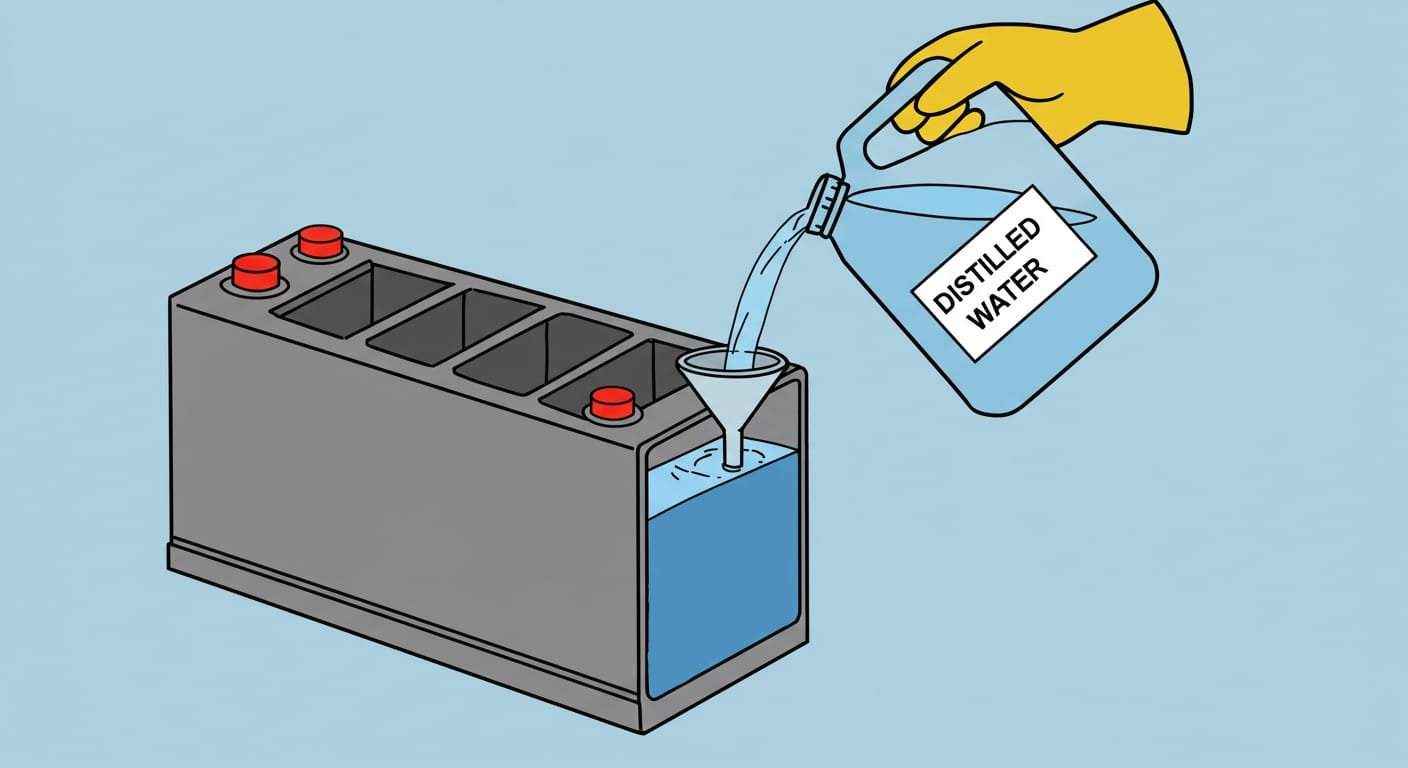

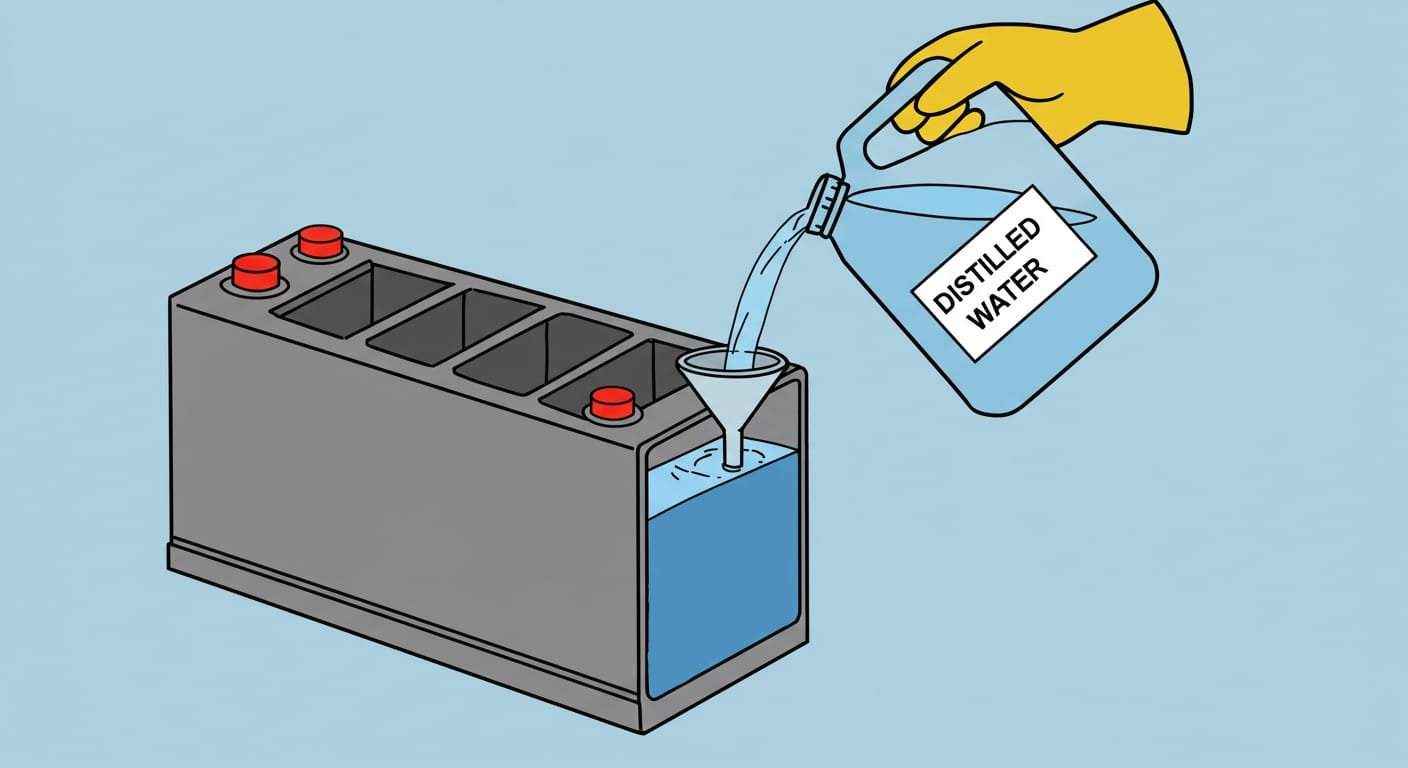

Step-by-Step: How to Manually Water a Forklift Battery

Manual watering is still common across the West Midlands, especially for smaller fleets. Here’s how to do it right.

What you need:

- Distilled or deionised water (never tap water)

- Battery watering gun, jug or bottle with pressure control

- PPE: goggles, gloves, apron, and protective clothing

- Flashlight (to check water levels clearly)

Step-by-step process:

- Safety first: Ensure the truck is off and parked on level ground. Remove the key. Make sure the battery has finished charging and has cooled.

- Wear PPE: Goggles, gloves, long sleeves, and an apron are non-negotiable.

- Open the battery compartment: Carefully lift the battery cover. Make sure the area is ventilated so that hydrogen gas cannot accumulate.

- Remove vent caps: Unscrew or flip up the caps on each battery cell.

- Check electrolyte level: Use your flashlight to ensure the lead plates are covered but not flooded.

- Top up each cell: Slowly add distilled water until the electrolyte reaches just below the fill tube or indicator. Avoid overfilling.

- Replace caps: Securely fit each cap back in place to prevent evaporation and contamination.

- Clean up: Wipe down any spills with a damp cloth and dispose of it correctly.

A quick job done poorly can ruin a battery. Take your time or better yet, let professionals handle it.

Should You Use an Automated Watering System?

If you’re managing more than a few trucks, automated watering systems are a smart upgrade.

These systems connect to each battery cell and regulate water flow automatically. Just hook up the hose, and the system fills each cell to the correct level without over- or under-watering.

Benefits of battery watering systems:

- Uniform water levels across all cells

- Less manual labour

- Reduced risk of acid spills

- Quicker maintenance – no need to check each cell

But they’re not set-and-forget. You still need to:

- Check for blocked valves

- Inspect for wear and leaks

- Do random “pilot cell” inspections

At Easy Truck, we often recommend automated systems for mid-to-large fleets looking to reduce errors and increase battery reliability.

What Are The Common Mistakes to Avoid?

Some of the most expensive battery problems come from well-meaning operators skipping key steps. Here are the ones we see most often:

- Filling before charging – Causes overflow and acid loss.

- Using tap water – Minerals cause scale build-up and shorten battery life.

- Overfilling cells – Leads to acid spills, damaged cables, and corrosion.

- Infrequent checks – Weekly checks are better than quarterly surprises.

- Poor record keeping – If you don’t track it, you can’t improve it.

Training your team properly and sticking to a schedule can prevent nearly all of these issues.

Easy Truck’s Maintenance Strategy & Recommendations

At Easy Truck, we take battery maintenance seriously. We don’t just supply forklifts across the West Midlands we keep them working.

Here’s how we help our customers extend battery life:

- Integrated PM schedules that include regular battery checks

- Automated watering system installations for larger operations

- Staff training to promote safety and best practices

- Battery audits to assess condition, water levels, and charging behaviour

Want to cut your running costs and reduce battery-related downtime? Let us help you build a strategy that works.

Tips for Effective Forklift Battery Maintenance

At Easy Truck, we’ve seen that small habits lead to big savings. Here are three we always recommend:

- Keep a schedule: Planned maintenance keeps your battery operating at its best. Weekly inspections and consistent watering routines reduce the risk of surprise failures.

- Monitor battery health: Don’t just focus on water levels. Watch for signs of physical damage, poor charge retention, or overheating. Spotting small issues early prevents major repairs later.

- Consider a watering system: If you’re running a fleet, a battery-operated automated watering system can save hours each week and remove the guesswork.

Your forklift battery isn’t just a part it’s a performance multiplier. Look after it, and it looks after your business.

Your Forklift Battery Maintenance Checklist

To make your battery care routine even easier, we’ve put together a clear and practical Forklift Battery Maintenance Checklist.

It includes daily, weekly, and monthly checks, covering everything from visual inspections to fluid top-ups and system reviews ideal for warehouse managers and maintenance teams.

Using this tool alongside your internal processes will help prevent costly breakdowns and extend battery lifespan across your fleet.

Conclusion & Next Steps

Battery watering isn’t complicated but it is critical.

By understanding the why, when, and how of proper battery hydration, you’ll avoid costly failures, extend the life of your trucks, and keep your warehouse moving.

If you’re thinking of formalising your battery maintenance or weighing up automation options, our team can provide practical guidance based on real fleet experience. From sourcing the right equipment to ongoing support, we’re ready to help you keep your operation efficient and stress-free.