A Guide To Forklift Tyres: Comparing Indoor and Outdoor Uses

So, you’ve just bought, leased, or hired a brand-new forklift truck—or maybe you’re planning to buy one soon. Whether you’re a seasoned forklift pro or just starting to explore the material handling industry, you’re likely curious about how to get the most out of your forklift. A key part of that is understanding which type of tyre will help you maximize your equipment’s performance.

Understanding the most suitable tyre type for your forklift, as well as its lifespan, is essential to optimising performance and safety of handling operations on your premises. Your fork truck, goods, and operator safety are all affected by your forklift tyres.

Commonly available are pneumatic and cushion ‘press on band’ tyres; we further look at polyurethane and tyres designed for more specialised applications in this introduction to forklift tyres.

These varying tyre types all require individual handling and maintenance, so ensuring you’re up-to-date on the latest advice surrounding your forklift tyres will keep your operations running smoothly.

What are the Different Tyre Types?

When choosing fork truck tyres, there are several different types including pneumatic, cushion, polyurethane, and specialised tyres.

The most suitable tyre for your application is based on considerations such as: manufacturer specifications of the forklift, the load and run requirements of your handling operations, and surface conditions.

Pneumatic

Pneumatic tyres are a common rubber tyre, available as a solid or air-filled model. Both offering a range of advantages across indoor and outdoor applications, solid and air-filled pneumatic tyres can be used for all types of handling operations.

Solid

Solid pneumatic tyres are an incredibly durable option, being, as the name suggests, made from solid rubber.

This makes them resistant to punctures, increasing their longevity even when handling heavy loads. And while they may be more expensive upfront, their durability and long-lasting nature make them a cost-effective investment in the long run.

Air

Similarly to a car or truck, these pneumatic tyres are inflated with air and offer increased comfort to the driver as well as reduced weight compared to their solid rubber counterpart.

Air filled tyres are ideal for outdoor use and provide greater cushioning, particularly over uneven surfaces. With a deep tread design, they offer excellent traction and grip.

Whilst durable and long-lasting, air-filled tyres are susceptible to punctures, so it’s important to regularly inspect them for any signs of damage. Proper inflation is also crucial for optimal performance and safety.

When Should I Replace My Pneumatic Tyres?

Replacing pneumatic tyres should be undertaken when signs of wear and tear are showing. This could include: bald patches on the tyre; showing internal cord or fraying; having less than 1.6mm tread depth over the majority of the tyre.

Worn-out tyres can affect the forklift’s stability and traction, leading to potential accidents. Additionally, over or under-inflated tyres can also impact the forklift’s performance and efficiency.

Cushion/ Press On Bands

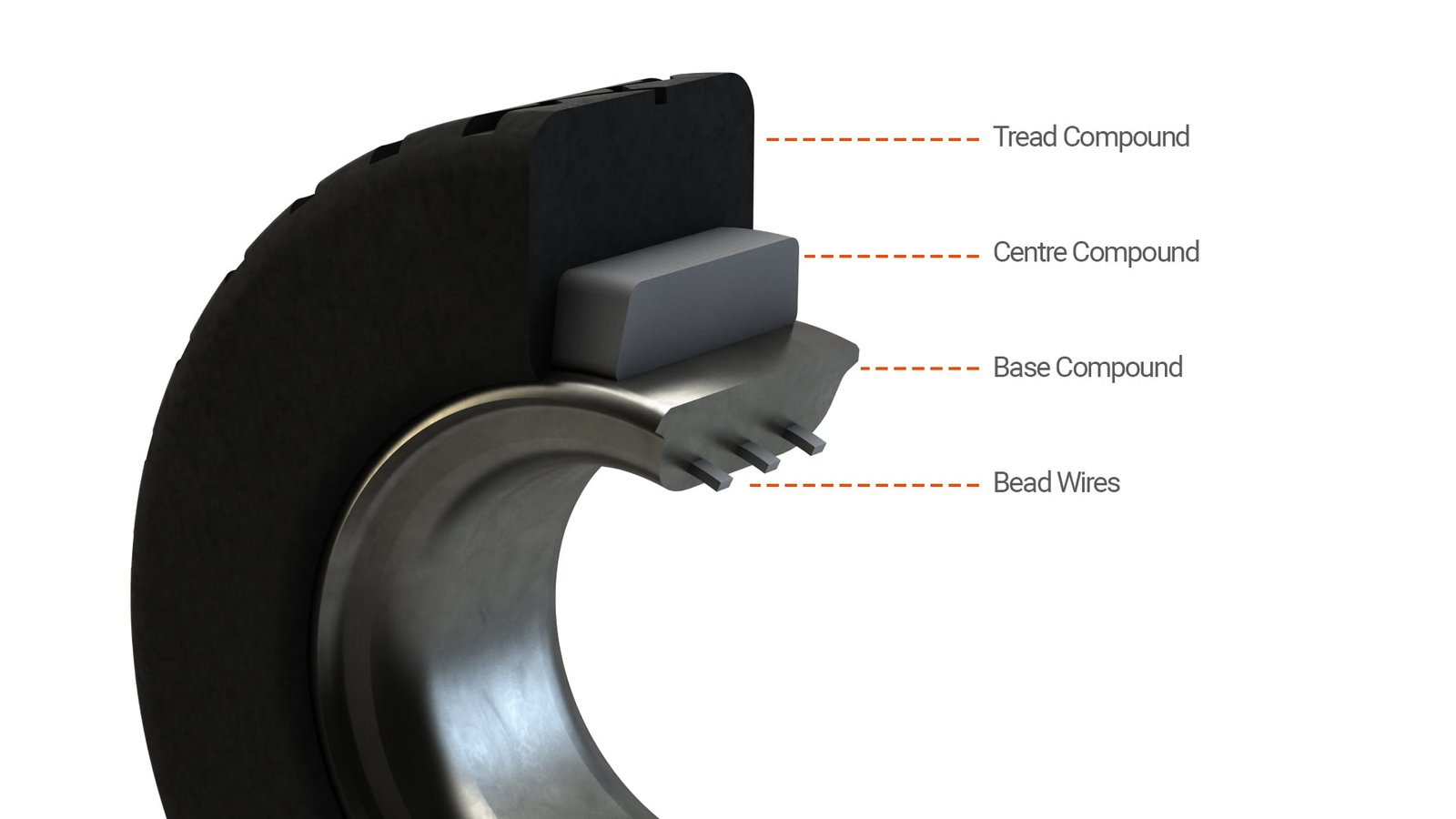

Another popular tyre type, cushion tyres (also known as press on band tyres), are differentiated from pneumatic tyres because of their manufacturing and installation process. These tyres are manufactured from a solid rubber tread bonded to a steel band and are pressed onto the wheel.

Suitable for both indoor and outdoor applications, this engineered tyre is available with a smooth or traction tread.

Advantages and Disadvantages

Cushion tyres offer advantages such as comfortable operation, especially on smooth surfaces like concrete and asphalt or indoor applications. Their smaller size and turning radius also make them more manoeuvrable in tight spaces, increasing efficiency.

However, these fork truck tyres may not be suitable for heavy lifting duties or uneven surfaces, and they are susceptible to tearing.

When Should I Replace My Cushion Tyres?

Generally, cushion tyres should be replaced when they reach or go beyond the 50% wear line.

However, you may notice other signs of wear, such as: pieces falling off the tyre, tearing, or flat areas in one part of the tyre. Continuing to use worn-out cushion tyres can lead to safety hazards, decreased performance, and potential damage to your forklift.

Why Are They Called Press On Band Tyres?

Cushion tyres are commonly called press on band tyres because these tyres are pressed onto the wheel using specialised equipment, such as press machines, during installation.

Polyurethane

Polyurethane tyres, also known as bonded tyres, offer great durability and long-lasting performance in indoor forklift applications.

Advantages and Disadvantages

Polyurethane tyres excel in indoor environments, particularly for operations handling chemicals and other aggressive substances. Polyurethane offers high chemical resistance, ensuring durability in these conditions.

On the other hand, polyurethane tyres are prone to punctures due to their lack of tread, especially on rough or uneven surfaces, limiting their usage to clean, indoor surfaces.

When Should I Replace My Polyurethane Tyres?

Signs like cracking, tears, chunking, and ‘meltdown’ are indicators that it’s time to replace your polyurethane tyres. These issues are typically caused by overuse, which creates excessive internal heat and leads to the deterioration of the tyres.

Specialised Tyres

The tyres listed here are not so common in general forklifting applications, but may be considered for enhanced performance in specific environments.

Ranging from driving on frozen surfaces to handling combustible materials, these specialised tyres offer improved efficiency and safety in demanding situations.

Walnut Winter Tyres

Walnut winter tyres are specially designed to increase traction on icy terrains. By incorporating coarsely ground walnut shells into the rubber tread, these tyres act as studs, providing superior grip and stability.

Unfortunately, these tyres are not available for fork trucks. Instead, when operating in freezing, icy, or winter conditions, it is recommended that pneumatic tyres are used; both air-filled and solid pneumatic tyres are suitable for these surface conditions.

You can further enhance the performance of pneumatic tyres with chains and studs, which increase traction and grip.

Anti-Static Tyres

Anti-static tyres are designed to prevent static discharge in non-marking tyres, eliminating the risk of electric shock.

These tyres are also crucial for handling combustible and explosive products, as they produce virtually no static discharge that could ignite fumes or flammable materials. By using anti-static tyres on your forklift, you can significantly decrease the likelihood of accidents and ensure a safer working environment.

Non-Marking Tyres

Non-marking tyres won’t leave a black mark on the floor surface, ensuring your premises are kept clean and professional.

Unlike traditional black tyres which can leave unsightly marks on surfaces, non-marking tyres are made from a softer compound and are finished in a light colouring, commonly white. This makes them suitable for low-maintenance industrial floors as well as commercial environments, such as retail spaces, airports, and medical sectors.

Fibreglass Tyres

Fibreglass tyres are designed to withstand high temperatures, making them a perfect choice for industries where heat tolerance is crucial. The fibreglass reinforcement in these tyres helps to prevent melting or deforming, ensuring a longer lifespan and increased safety for your forklift operations.

How Can I Maintain My Fork Truck Tyres?

Establishing a maintenance schedule, training operators on correct driving practices, regularly inspecting forklift tyres and properly storing them are all ways in which you can maintain your tyres and prevent damage.

How can I maintain My Forklift?

We have carefully crafted an article that outlines our manufacturer standard forklift refurbishment process. Our expert Rich has provided some top tips for forklift maintainance. Click the link to see Rich’s Tips For Forklift Longevity and our forklift refurbishment process.

How to Prevent Damage

To keep your forklift tyres in top condition, make sure to schedule regular maintenance and undertake inspections of your forklift and tyres in between services, helping you to stay ahead of any potential issues.

Training operators on correct driving practices and handling procedures is also at the centre of maintaining your forklift tyres. For example, overloading the forklift and harsh acceleration/ braking can put excessive strain on the tyres.

Additionally, keeping your premises clean and clear of any debris which may damage or puncture the tyres is key.

How to Store Fork Truck Tyres

Properly storing fork truck tyres is crucial to maintaining their quality and longevity in order to avoid unnecessary damage.

When storing fork truck tyres, it’s important to keep them in a cool, dark place that is free from substances which can corrode or damage the rubber; this includes grease, petrol, oil, and more.

Additionally, storing tyres away from direct sunlight can help prevent premature ageing and cracking. Having a well-ventilated space will also help prevent moisture buildup, which can contribute to tyre degradation.

The various types of tyres available for forklifts allows you to select the most suitable solution for your handling operations. Whether prioritising driver comfort, or durability on rough terrain, investing in the right tyre type is essential to performance and safety. To ensure this effect is lasting, make sure to practise maintenance and follow recommended procedures to keep your tyres in top condition.

How Often Should I Change My Forklift Tyres?

Replacing old fork truck tyres depends on several factors. The type and quality of the tyre, forklift usage, the environment and handling application, driver skills and behaviour, and even temperature are all variables which affect how often you should change your forklift tyres.

If you’re concerned about levels of wear and tear or notice a change in the operation of your forklift, you may require a replacement service.

Regularly inspecting and replacing forklift tyres can help prevent accidents, improve traction, and extend the lifespan of your equipment.

Can I Change My Forklift Tyres?

Changing forklift tyres is a task best left to professionals. The type of tyre you have will determine the complexity of the process; press-on tyres require a specialist machine to be installed, while pneumatic air-filled tyres need to be inflated inside a tyre cage for the first time.

It’s crucial to ensure that tyres are properly installed – using a professional for this task will guarantee that the job is done correctly and safely.

Why Do I Need to Replace Forklift Tyres?

Replacing worn-out tyres on your fork truck is essential to maintain safety and efficiency in the workplace. Continuing to use worn or damaged tyres can result in:

- Decreased traction, making it harder to control the forklift and increasing the risk of accidents.

- Uneven weight distribution, putting additional stress on the forklift and potentially causing mechanical issues.

- Instability, making it more likely for the forklift to tip over while in operation.

By replacing worn-out tyres promptly, you ensure that your forklift operates smoothly, reducing the risk of workplace injuries, damage to goods, and further costly repairs.